Where can diesel powered vertical turbine pumps be used?

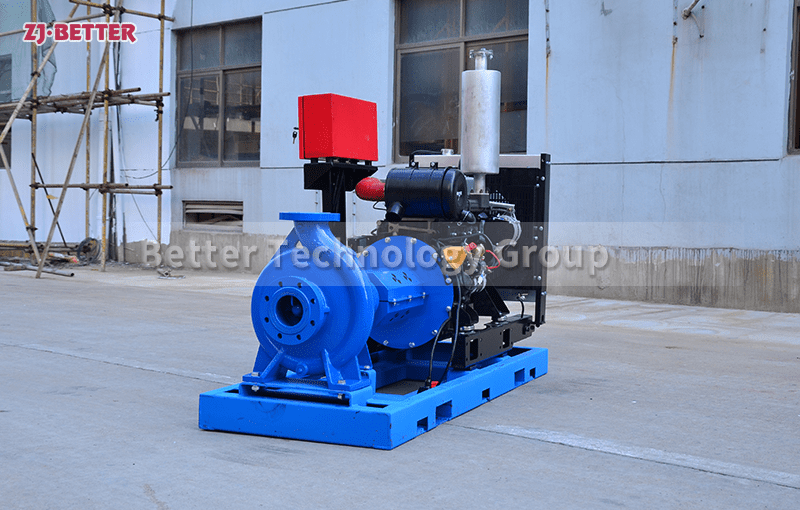

Vertical turbine pump is a kind of centrifugal water pump, which is used to deal with non-corrosive clear water at normal temperature. The main working part is the impeller, which can generate centrifugal force through high-speed rotation to achieve the function of lifting water. In a group of cases, it only needs to match the head, flow rate, power and other requirements. There will be no problem.

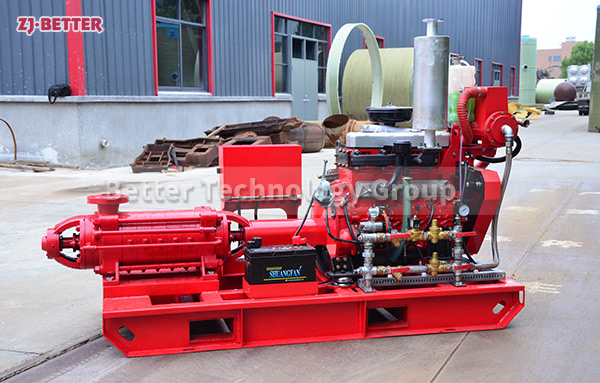

The vertical turbine pump has a longer insertion depth during operation, and the overall length of the long-shaft vertical pump is longer. It is often used in rivers or offshore platforms and other working conditions that need to be inserted into a long depth. Generally, it is the first stage double suction, if the head is high, it is recommended to use a multistage centrifugal pump.

Vertical turbo pumps can be used to transport clean water, rainwater, sewage, seawater, corrosive industrial wastewater, etc. below 55°C. After special design, it can transport liquid at 90°C. It is widely used in power plants, steel plants, water companies, sewage treatment plants, mines and other enterprises, as well as municipal water supply and drainage, flood control and drainage projects.