Why Is a Diesel Engine Fire Pump System the Key to Fire Safety?

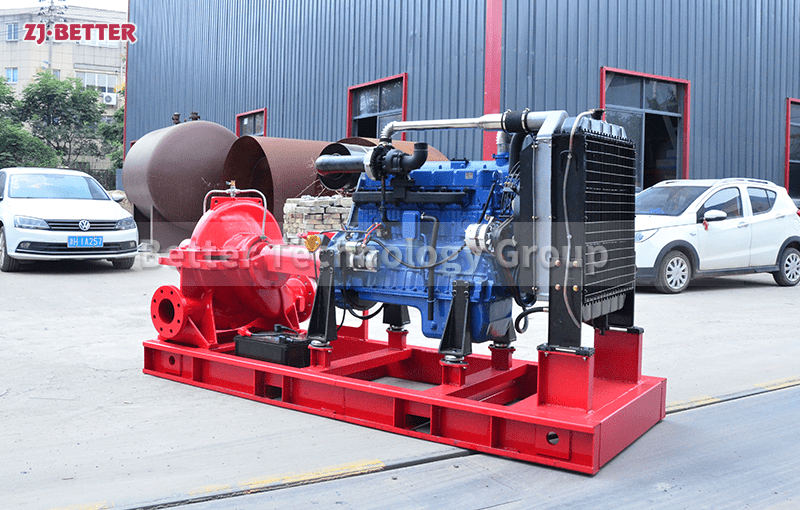

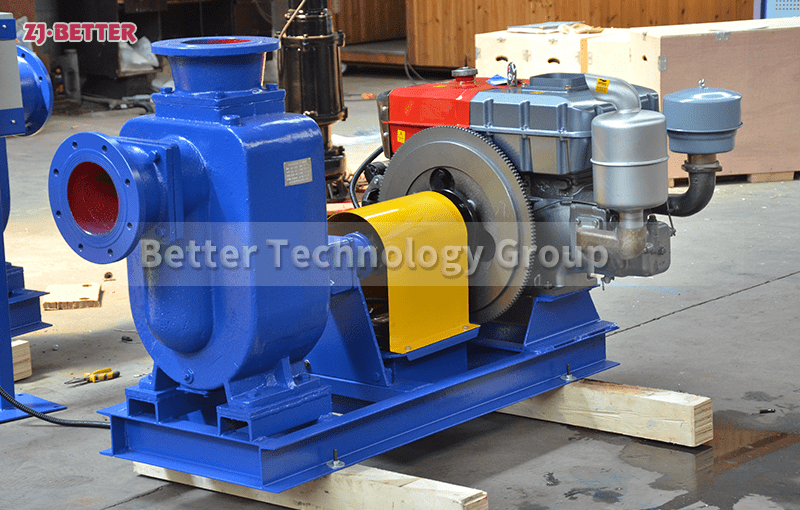

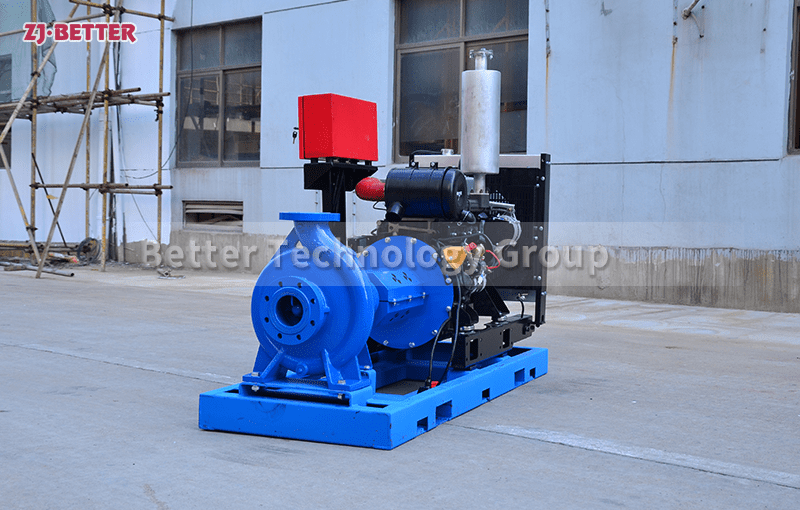

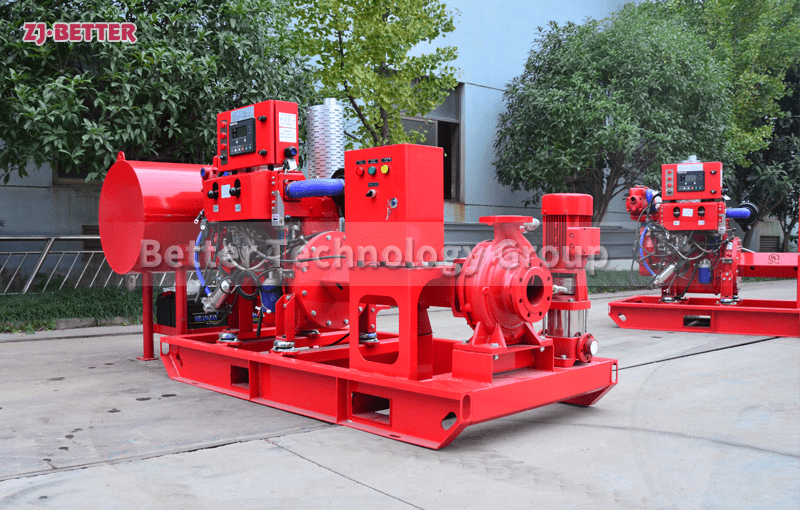

The diesel engine fire pump system plays a vital role in modern fire protection systems. Unlike traditional electric pumps, its greatest advantage lies in its independent power supply. Even during power outages or electrical failures, it can start immediately and continuously deliver strong water flow to ensure the fire suppression system functions properly. With powerful performance and exceptional durability, it remains stable and reliable even in high-temperature, high-humidity, and harsh environments. Its compact structure saves space, making installation and maintenance easier. It is ideal for industrial plants, warehouses, high-rise buildings, and other applications. Choosing the ZLBETTER diesel fire pump system is a smart decision to enhance fire safety and protect lives and property.

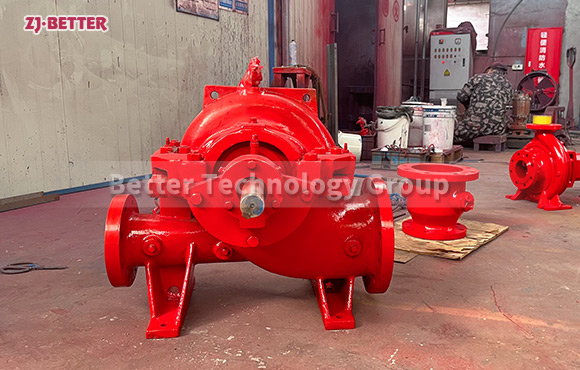

We specialize in the research and manufacturing of high-performance fire pump systems, dedicated to providing efficient and reliable fire protection solutions for users worldwide. Our product range includes electric fire pumps, diesel engine fire pumps, complete fire pump sets, and intelligent control systems, widely applied in commercial buildings, industrial facilities, and municipal projects.

Our fire pump systems feature fast start-up, stable water supply, and high operational efficiency, ensuring a quick response in emergency situations. The equipment is compact in design, robust in structure, and flexible in installation, making it adaptable to various environmental conditions. The integrated intelligent control system offers powerful functions such as automatic start/stop, fault alarms, status monitoring, and remote management, greatly enhancing the system’s intelligence and ease of operation.

All products undergo rigorous testing and are characterized by excellent interference resistance, corrosion protection, and long-term operational stability—making them an ideal choice for modern fire protection systems. We are committed to continuously advancing product performance and using technological innovation to safeguard every aspect of safety.