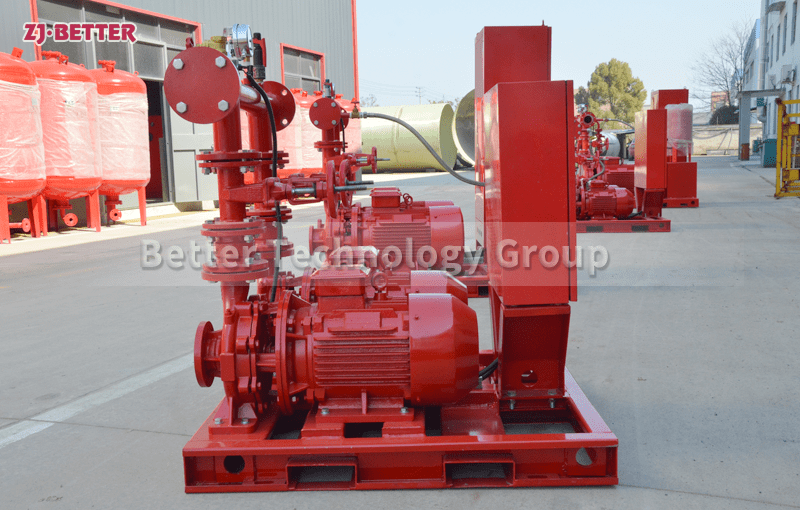

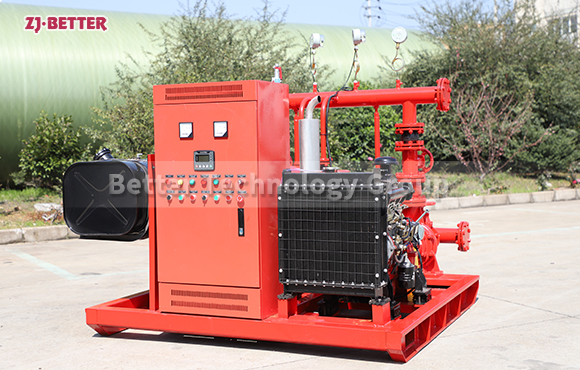

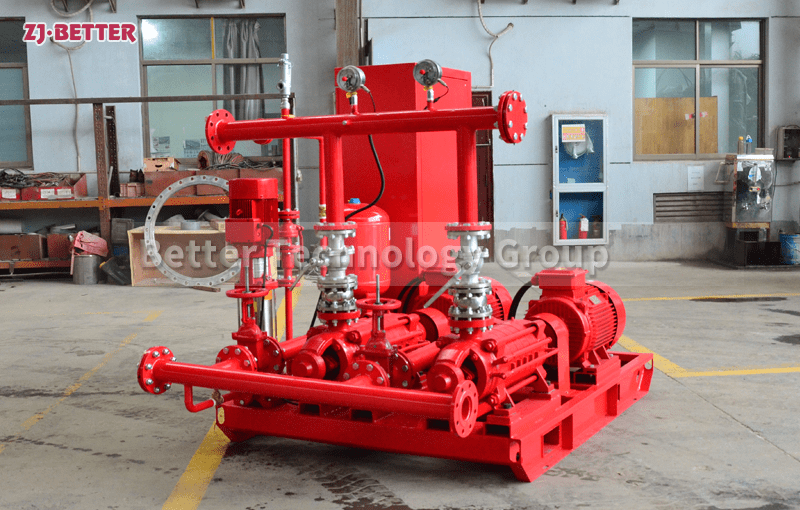

XBC-D 127KW Diesel Engine Multistage Pump

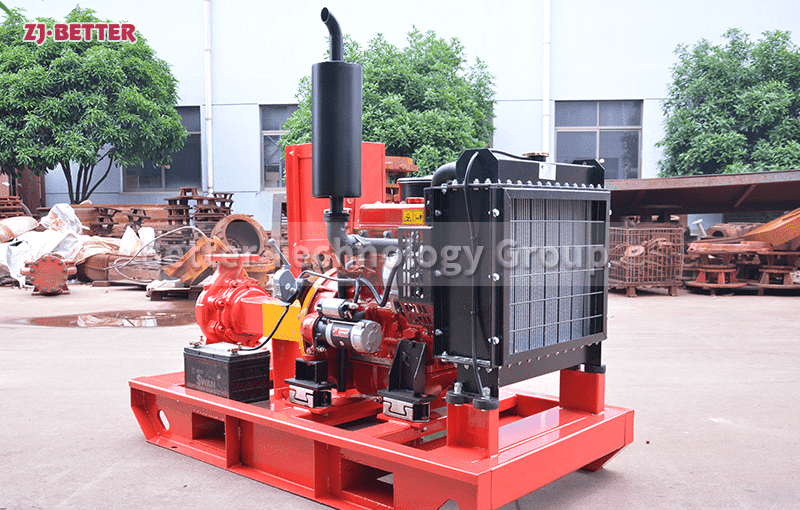

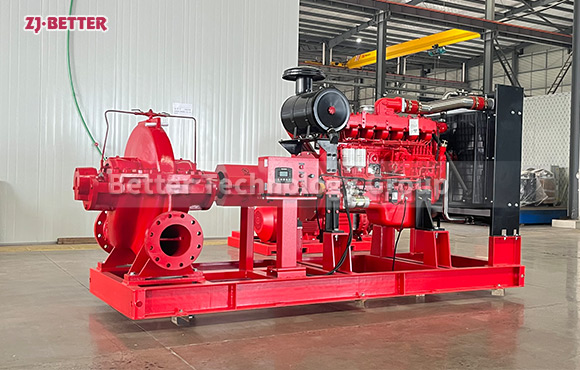

A multistage pump refers to a pump with two or more impellers, which can absorb and press water in multiple stages, so as to lift the water to a high position. The lift can be increased or decreased according to the needs of the pump impeller. The multistage pump can be equipped with a four-stage motor by increasing the number of impellers when the single-stage pump head needs to be equipped with a two-stage motor, which can improve the service life of the pump and reduce the noise of the unit.

Compared with the single-stage pump, the difference is that the multi-stage pump has more than two impellers, which can absorb and press water in multiple stages, so as to lift the water to a very high position, and the lift can be increased or decreased as needed. The number of stages of the pump impeller. Multi-stage pumps are mainly used for mine drainage, urban and factory water supply, and rarely used for agricultural irrigation.