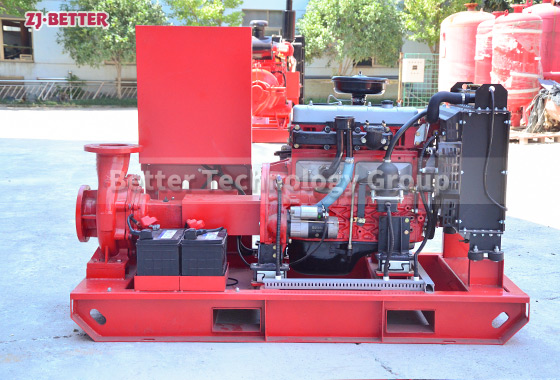

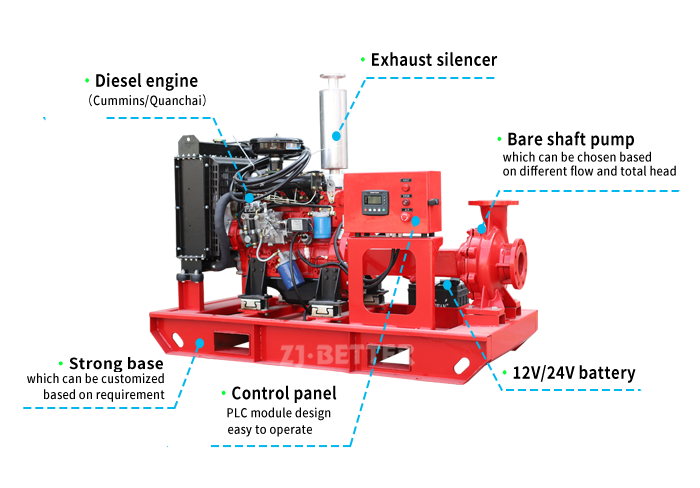

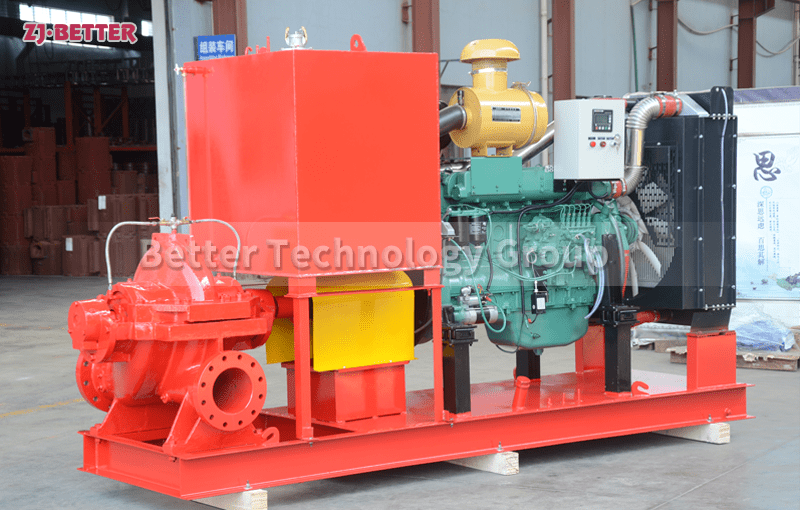

XBC-IS Fuel-Powered Fire Pumps

Flow:80-2700 GPM

Head:10-24 Bar

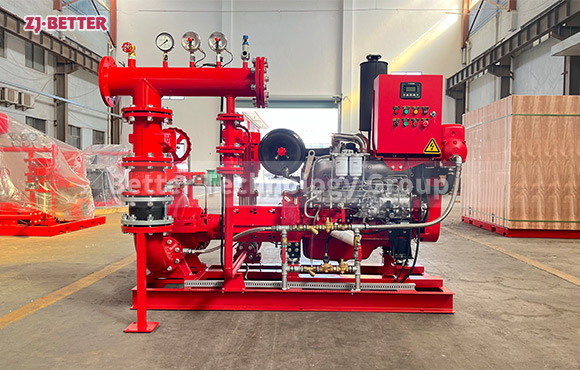

XBC-D Diesel Fire Pump Set is a versatile and reliable firefighting solution designed for a wide range of applications. Whether it’s industrial facilities, commercial buildings, residential complexes, or public infrastructure, the XBC-D Diesel Fire Pump Set ensures effective fire protection. With its robust design and advanced features, this pump set is ready to tackle emergencies and safeguard lives and properties in various firefighting scenarios.

1.Automatic Operation: The XBC-D Diesel Fire Pump Set features automatic operation. In case of a power failure, the system automatically switches to diesel engine drive, ensuring a continuous supply of firefighting water pressure.

2.Alarm System: Our product is equipped with an advanced alarm system that monitors and alerts operators in real-time about the status and faults of the fire pump set, ensuring fire safety.

3.Multiple Startup Methods: The XBC-D Diesel Fire Pump Set supports various startup methods, including fire signal startup, manual startup, and remote startup, ensuring quick activation of the fire pump set in emergency situations.

4.Direct Coupling Design: Our product adopts a direct coupling design, featuring high transmission efficiency and torque transfer, effectively isolating the vibration from the diesel engine, ensuring durability.

5.Automatic Charging Function: The XBC-D Diesel Fire Pump Set can charge using the mains power supply and automatically charges when the battery voltage is low. When the battery voltage is sufficient, the system automatically stops charging, avoiding battery damage.