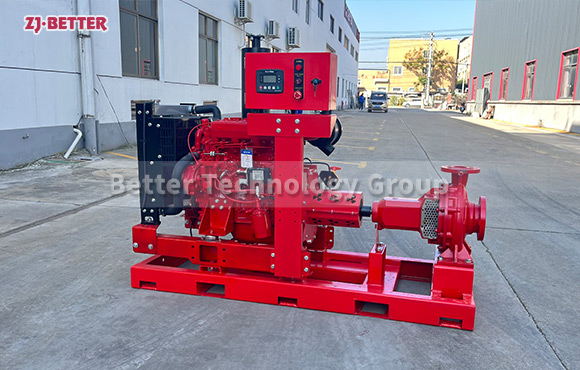

XBC-ISO Diesel Fire Pump: Your Ultimate Fire Safety Solution

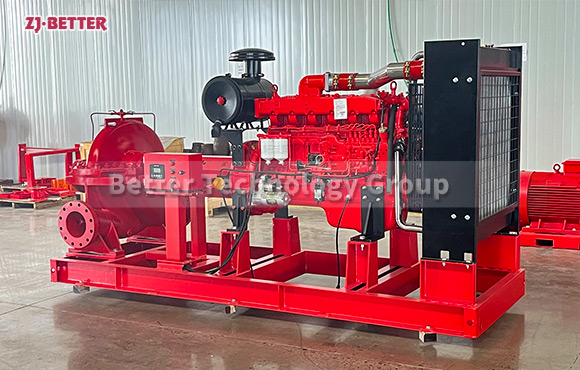

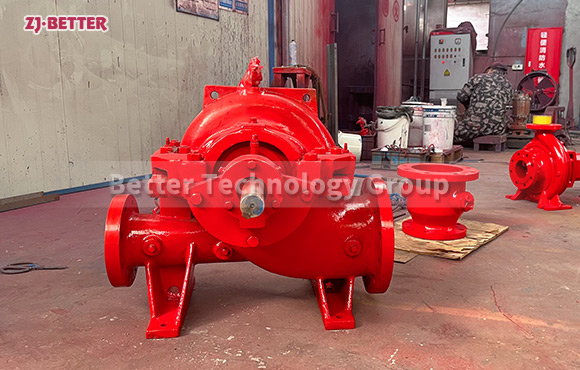

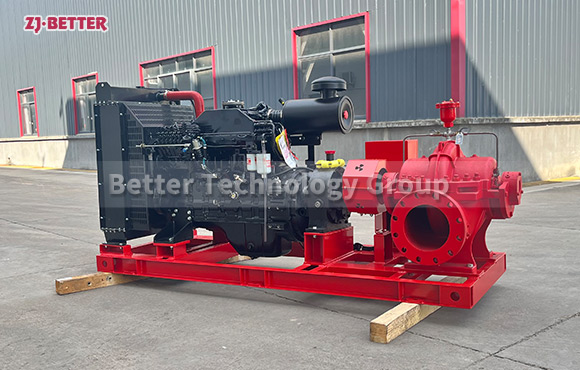

The XBC-ISO Diesel Engine Fire Pump Set is an efficient and reliable firefighting equipment that combines the power of a robust diesel engine with the advantages of an ISO single-stage centrifugal pump. This pump set is ISO certified, ensuring excellent quality and performance. The XBC-ISO pump set is suitable for emergency firefighting scenarios, particularly ideal for high-rise water supply, building firefighting, central air conditioning water circulation, industrial process system circulation, cooling systems, boiler water supply, industrial water supply and drainage, water plant supply, irrigation in plantations, and more. This firefighting pump set is equipped for emergency rescues and can operate efficiently even during power outages. Moreover, its end-suction design simplifies operation and saves installation time.

1.Unmatched Reliability: Combining a diesel engine with an ISO single-stage centrifugal pump ensures stable and reliable pumping performance, catering to any firefighting emergency!

2.Emergency Rescue: Operating efficiently even during power outages, the XBC-ISO Fire Pump Set keeps you prepared for any urgent crisis!

3.Versatile Application: From high-rise water supply to building firefighting, from industrial process system circulation to water plant supply, the XBC-ISO Pump Set adapts to various scenarios, effortlessly handling firefighting emergencies of all kinds!

4.Robust Output: Designed for transporting clear water or weakly corrosive liquids without solid particles or fibers, ensuring efficient completion of firefighting tasks!

5.User-Friendly: With its end-suction design, the easy-to-use end suction inlet allows for quick installation and pumping, saving valuable time!

6.Energy-Efficient & Environmentally Friendly: Advanced technology reduces energy consumption, cutting operational costs while contributing to environmental preservation!

Be it firefighting emergencies or scenarios compatible with ISO standards, the XBC-ISO Diesel Engine Fire Pump Set serves as your powerful backup!