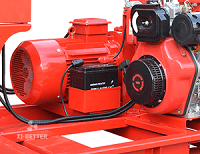

XBC-XA Diesel Pump

Application fields of XA fire pump:

For conveying clean water and liquids with physical and chemical properties similar to water;

Liquid pressurization devices of water works or water supply companies;

Circulation and cooling systems, boiler feed water, industrial water supply and drainage in industrial process systems;

Farmland irrigation and drainage, air conditioning system, urban water supply and drainage, fire protection system.

XA single-stage single-suction centrifugal pump conforms to international standards: ISO9908, Technical Specification for Centrifugal Pumps, Class III (Technical Specification for Centrifugal Pumps, Class III), mainly based on German DIN standard. Its dimensions and performance meet BS EN733 and DIN 24255 standards, making it interchangeable with other products that meet the requirements of this standard.

Structural design for easy installation: The rear opening cover design, the rotor parts can be replaced without removing the pipeline, and the sealing ring can be replaced. The wear of the impeller orifice ring can restore the best operating condition of the pump and realize the purpose of low-cost operation only by replacing the sealing ring.

Good suction performance: The suction section of the pump is of an expansion type structure, which reduces the flow rate of the pump inlet, so that the pump has good suction performance and a small necessary NPSH, which improves the service life of the impeller and the pump casing.