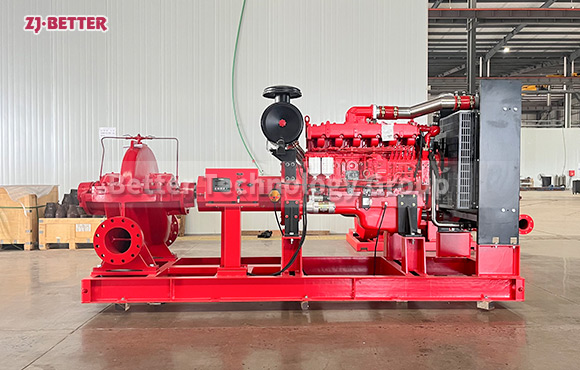

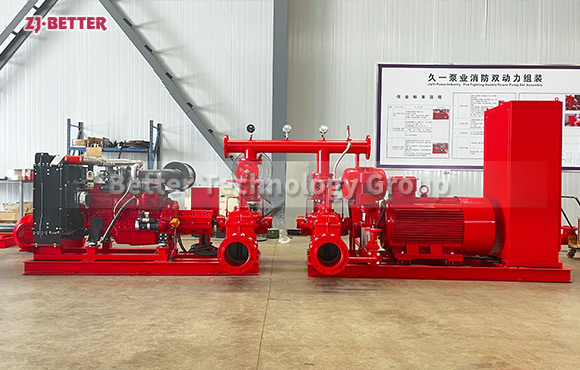

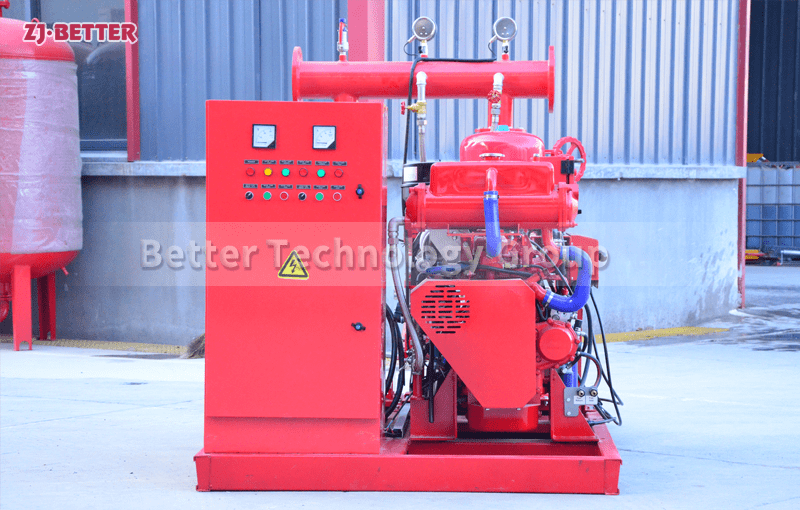

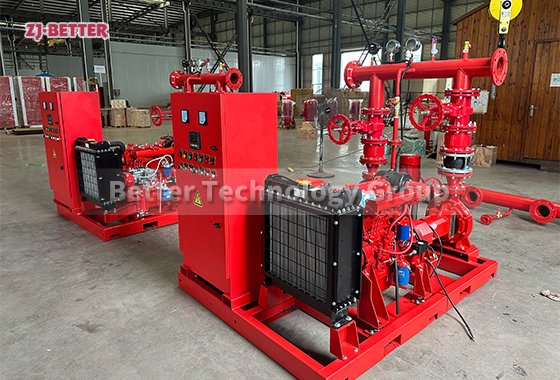

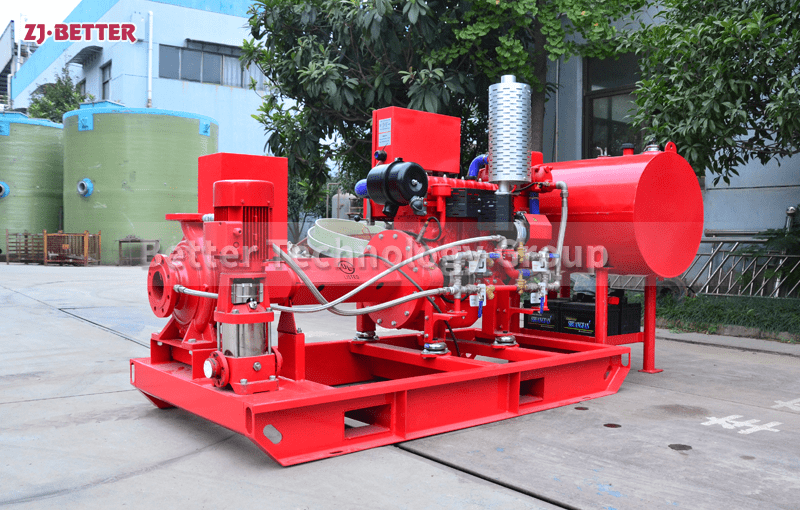

XBD-XA Fire Pump Equipment

The electric pump of this fire pump group adopts XA pump, which has good suction performance. The suction section of the pump is of an expanded structure, which reduces the flow rate of the pump inlet, so that the pump has good suction performance, a small necessary NPSH, and improves the prolongs the service life of the impeller and pump casing.

XA series single-stage centrifugal pump is the earliest single-stage single-suction centrifugal pump product launched by Better (China) Technology Co., Ltd.

This product combines the advantages of similar products in China and abroad, and is designed with excellent hydraulic model.Therefore, its excellent hydraulic performance and structural characteristics ensure that users can effectively reduce the operation cost of pumps in various applications.

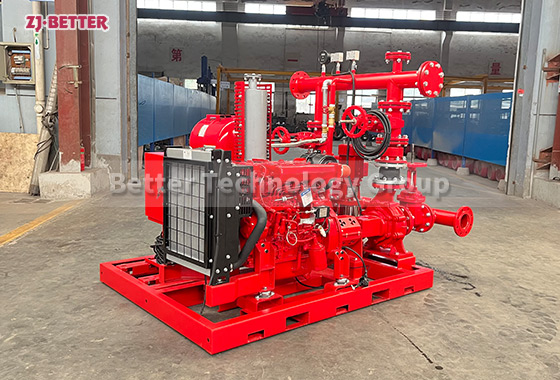

Structural Design for Easy Installation:

The rear open cover design can replace the rotor components without dismantling the pipeline.

Replaceable seal ring. The wear of the impeller ring can be achieved only by replacing the sealing ring, so as to restore the best operating condition of the pump and achieve low-cost operation.

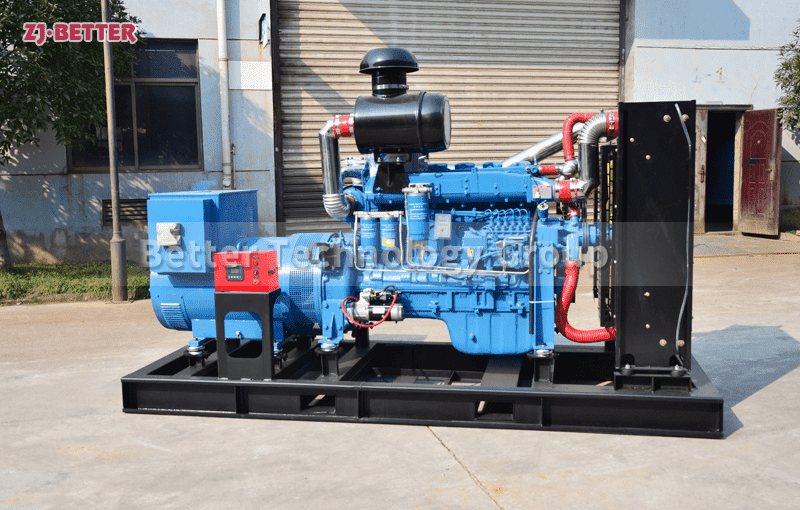

Ensure high reliability at high speed and heavy load operation