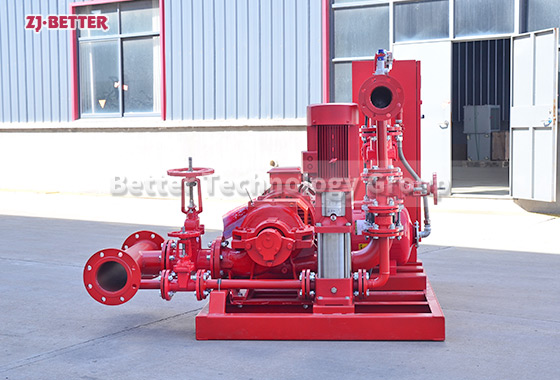

ZWX Non-Negative Pressure Water Supply Equipment: A Reliable Solution for Water Pressure Challenges

The ZWX box-type non-negative pressure water supply equipment is a pressurized water system designed to address inadequate municipal water pressure in critical settings such as hospitals and hotels, where water cannot be shut off. It also serves as an ideal solution for meeting the domestic water needs of high-rise buildings and, specifically, fulfilling the water requirements of schools. This equipment ensures a continuous water supply, even during maintenance or emergency situations, effectively resolving the challenges posed by low water pressure. With its efficient pressurized water supply and advanced control technology, the ZWX equipment offers stable water pressure and flow rates, catering to the diverse demands of different settings. Furthermore, its intelligent operation and energy optimization contribute to reduced energy consumption.

The ZWX box-type non-negative pressure water supply equipment is a pressurized water system designed specifically for places such as hospitals and hotels where water cannot be shut off but suffer from inadequate municipal water pressure. Additionally, this equipment is suitable for meeting the domestic water needs of high-rise buildings and is particularly well-suited for fulfilling the water requirements of schools.

Key features include:

- Solution for places where water cannot be shut off: The ZWX box-type non-negative pressure water supply equipment ensures a continuous water supply in locations where water cannot be interrupted, such as during maintenance or emergency situations. It effectively resolves the issue of insufficient municipal water pressure.

- Suitable for domestic water supply in high-rise buildings: This equipment provides stable water pressure and flow rate for high-rise buildings, catering to the daily domestic water needs of residents on multiple floors.

- Ideal for school water supply: The ZWX box-type non-negative pressure water supply equipment plays a vital role in schools, ensuring a consistent and stable water source for students and staff.

- Efficient pressurized water supply: The equipment pressurizes the municipal water supply, delivering stable high water pressure and large flow rates to meet various demands.

- Advanced control technology: The equipment incorporates advanced control systems, allowing for intelligent operation and optimization of energy usage, resulting in reduced energy consumption.

In summary, the ZWX box-type non-negative pressure water supply equipment provides a continuous water supply solution for critical locations such as hospitals and hotels. It also caters to the domestic water needs of high-rise buildings and is particularly suitable for meeting the water requirements of schools. With its efficient pressurized water supply and advanced control technology, it offers an ideal solution for ensuring a stable and reliable water supply.