Feature

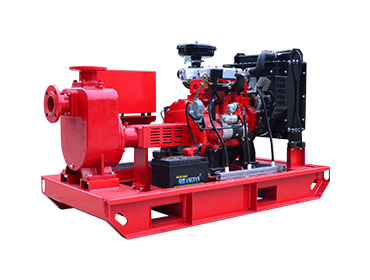

ISO end-suction pumps typically adopt the design of a centrifugal pump and have specific design requirements and features. Here are some features of ISO end-suction pumps:

1. ISO Standards: ISO end-suction pumps comply with the standards set by the International Organization for Standardization, ensuring that their design, manufacturing, and performance meet globally accepted norms.

2. Suction Inlet Design: The suction inlet of an ISO end-suction pump usually has a large diameter to facilitate effective fluid intake. This design reduces inlet velocity, minimizes suction resistance, and prevents excessive pump wear.

3. Compact Construction: ISO end-suction pumps are often designed to be compact, occupying minimal space and allowing for easy installation and maintenance. This is particularly important in industrial applications with limited space.

4. High Efficiency: The design and material selection of ISO end-suction pumps aim to deliver efficient pumping performance. They typically offer high flow capacities and can withstand high pressures.

5. Material Selection: ISO end-suction pumps provide a range of material options to suit different application requirements. These materials can accommodate various fluid mediums, including corrosive fluids and high-temperature liquids.

6. Wide Application: ISO end-suction pumps find extensive use in industrial sectors such as chemical, petroleum, pharmaceutical, food and beverage, water treatment, and more. They are employed for fluid transportation, circulation systems, heating and cooling systems, among others.

In summary, an ISO end-suction pump is an industrial pump that adheres to international standards, offering features such as efficiency, compactness, and material versatility. It is suitable for diverse industries and applications.

%E2%88%9A.jpg)

%E2%88%9A.jpg)

%E2%88%9A.jpg)

%E2%88%9A.jpg)